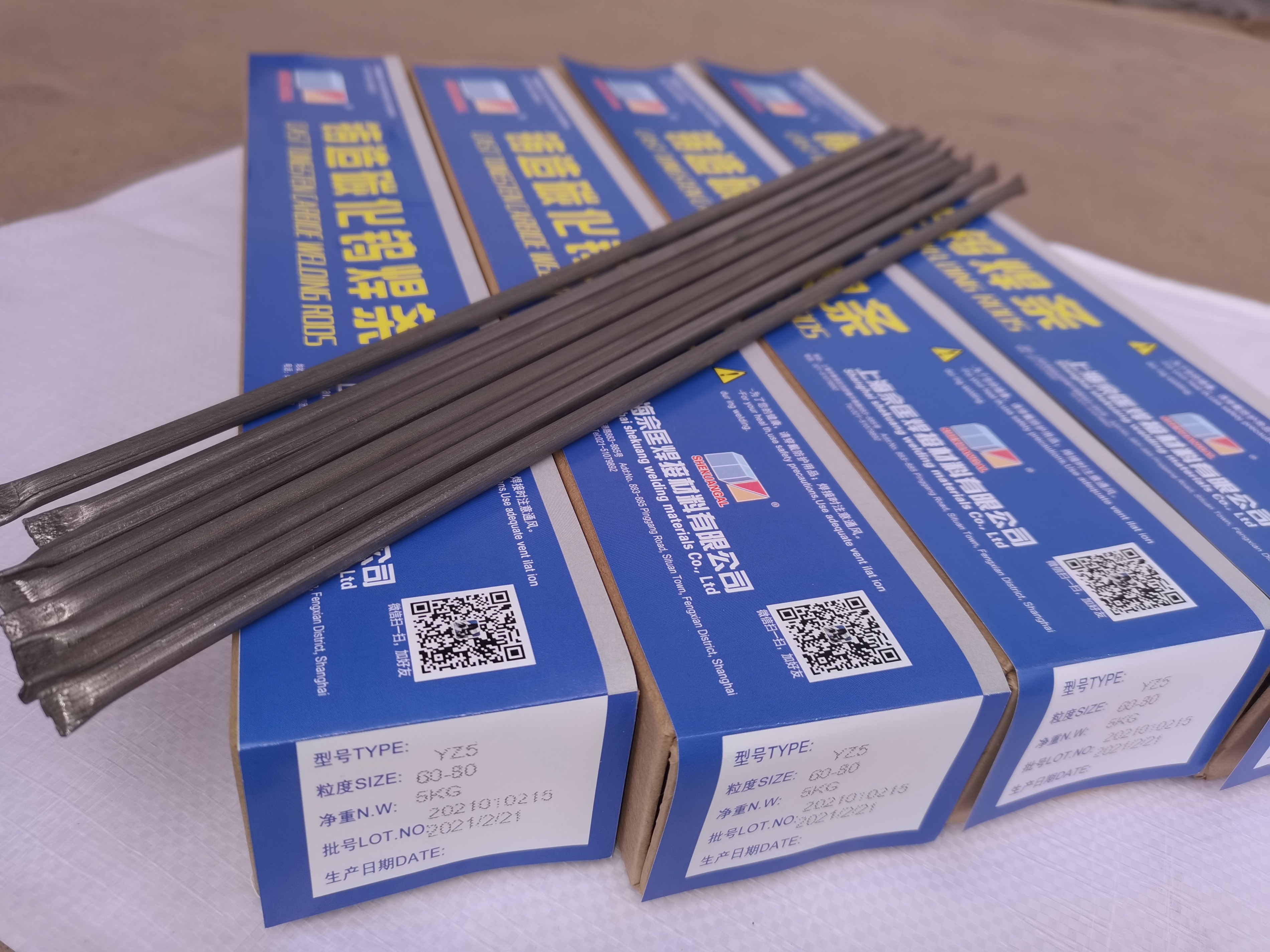

Wear-resistant electrode which good look she Kuang

Hardfacing hardness HRC≥70. Comply with GB984-2001 standard

The use of wear-resistant electrode is in the workpiece surface or edge of a layer of wear resistance, corrosion resistance, heat resistance and other properties of metal layer welding process. It has obvious economic benefit to repair and improve the service life of parts, rationally use materials, improve product performance and reduce cost. The surfacing work and working conditions are very complicated, and the appropriate electrode must be selected according to different requirements. Different workpiece and surfacing electrode must adopt different surfacing technology to obtain satisfactory surfacing effect.

Mainly used for chemical equipment and various mechanical equipment wear parts of the surfacing repair. Such as metallurgical machinery, mining machinery, turnout, jaw plate, bucket, shovel teeth, engineering quarries and other brick reamer, spiral, blender blade, fan blade, mineral processing machinery, construction machinery, building materials machinery, etc.

There is a direct relationship between cracking and the carbon content and alloying elements of the workpiece and weld metal deposited, so the preheating temperature is generally estimated according to the carbon equivalent of the electrode used. The following estimation formula is suitable for low, medium, high carbon steel and low alloy steel materials. The carbon equivalent formula is as follows: Ceq=C+1/6Mn+1/24Si+1/5Cr+1/4Mo+1/15Ni.

Carbon equivalent (%) Preheating temperature Carbon equivalent (%) preheating temperature

≤0 40100 ° C ≤0 70250 ° C

≤0,50150 ° C ≤0,80300 ° C

≤0,60200 ° C ≤0,90350 ° C

High manganese steel and austenitic stainless steel, without preheating. Preheating temperature of high alloy steel is higher than 400℃.

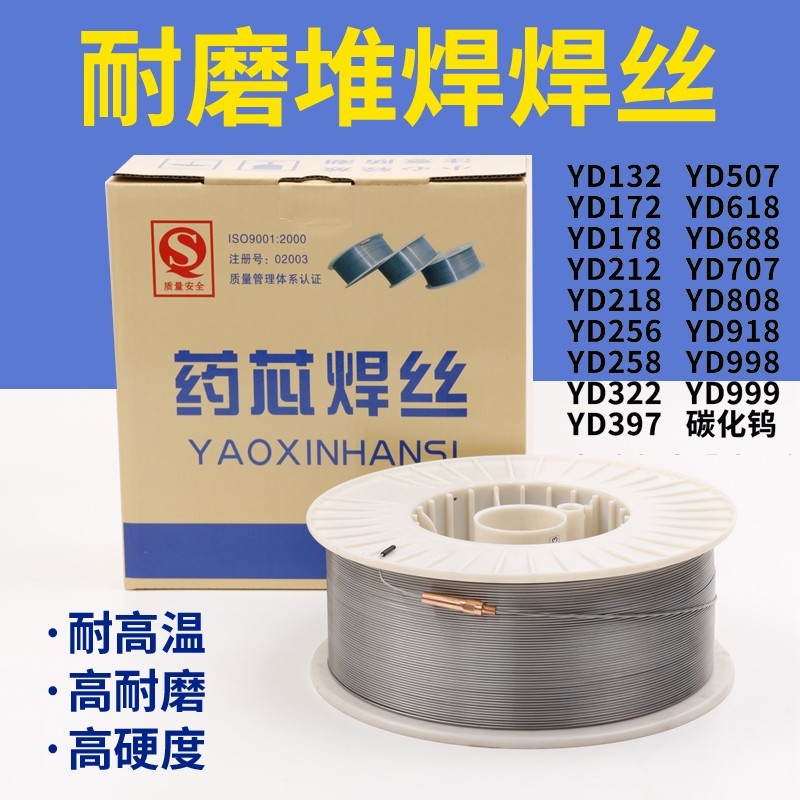

recommend products

Ranking of Similar Articles

- The silver electrode manufactu

- Wear resistant electrode selec

- Silver electrode manufacturer

- Wear resistant electrode - fol

- Wear-resistant electrode which

- Silver wire welding effect eff