Wear resistant electrode selection - guide expert

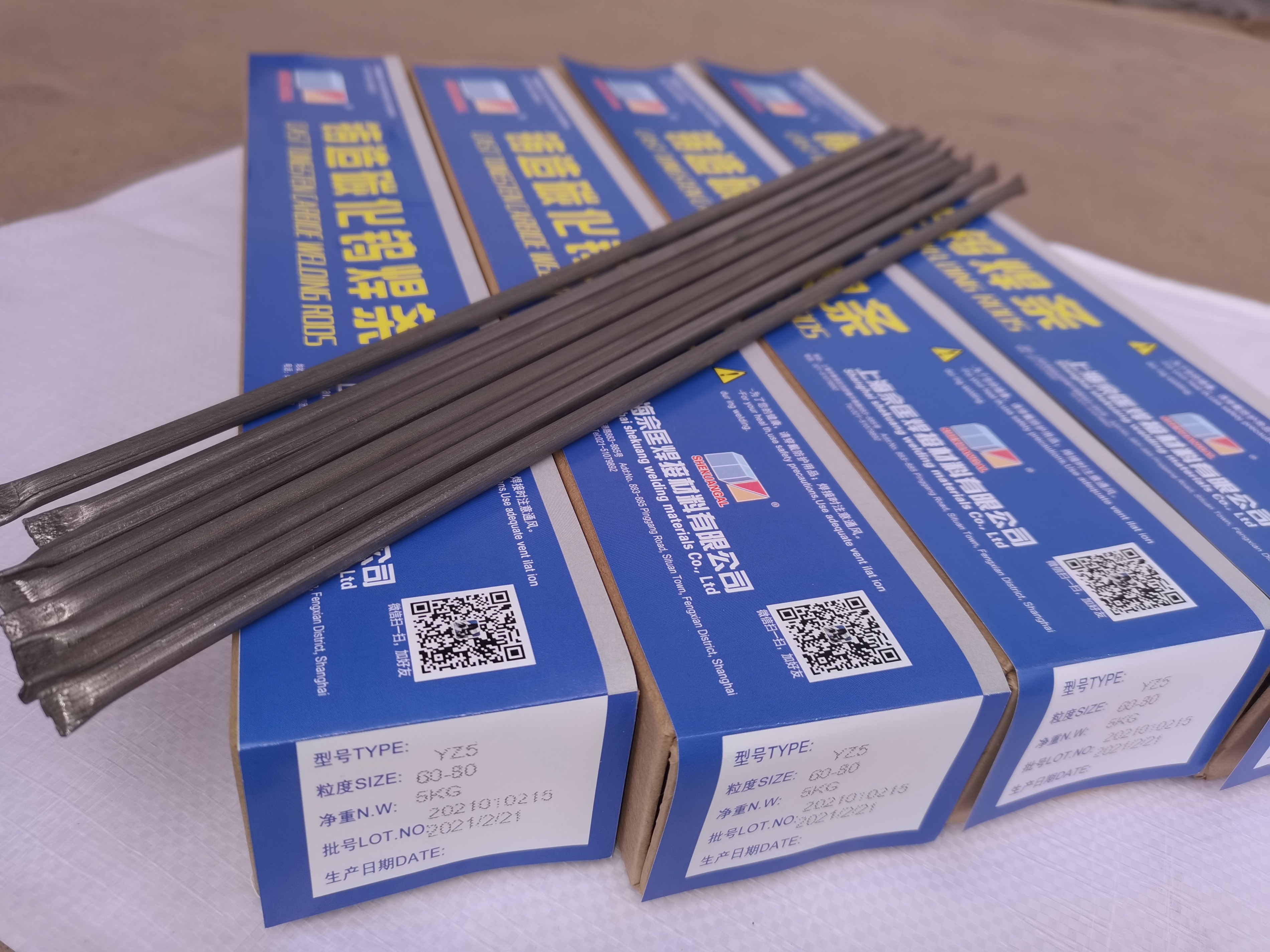

Tungsten carbide alloy wear-resistant electrode

Tdm-8 tungsten carbide alloy wear-resisting surfacing electrode building materials industry recommended products

The TDM-8 tungsten carbide alloy wear-resisting surfacing electrode produced by our factory is mainly developed for the wear characteristics of the transport screw, the blade of the mixer, the agger, the auger, the stick, the bulldozer push bucket, the digging bucket and the grab bucket of the brick and tile factory.

Tungsten carbide and sodium low hydrogen coating are used as the main raw materials, developed with Kobe technology in Japan, and can be cross-straight dual-use, the welding layer has high hardness, good toughness, high temperature resistance and wear resistance characteristics, used for surfacing of carbon steel, alloy steel, cast iron, cast steel and other surfaces.

Surfacing metal: high manganese steel core, tungsten content 57%, alloy powder 15%, ink cobalt chromium and other elements.

Chemical composition: W--57 Mo--17 C--0.05 Cr--9.8 B--4.2

Reference current:

Φ Φ Φ 4.0 5.0 3.2

90-120 - a 160-190 - a 190-220 - a

Hardfacing layer hardness (air cooling after welding) HRC≥75

Matters needing attention:

1, before welding, the sundries on the surface of the base material must be cleaned up.

2, should use small current, can prevent arc crack resistance.

3, such as thick welding layer can be repeatedly surfacing.

recommend products

Ranking of Similar Articles

- The silver electrode manufactu

- Wear resistant electrode selec

- Silver electrode manufacturer

- Wear resistant electrode - fol

- Wear-resistant electrode which

- Silver wire welding effect eff