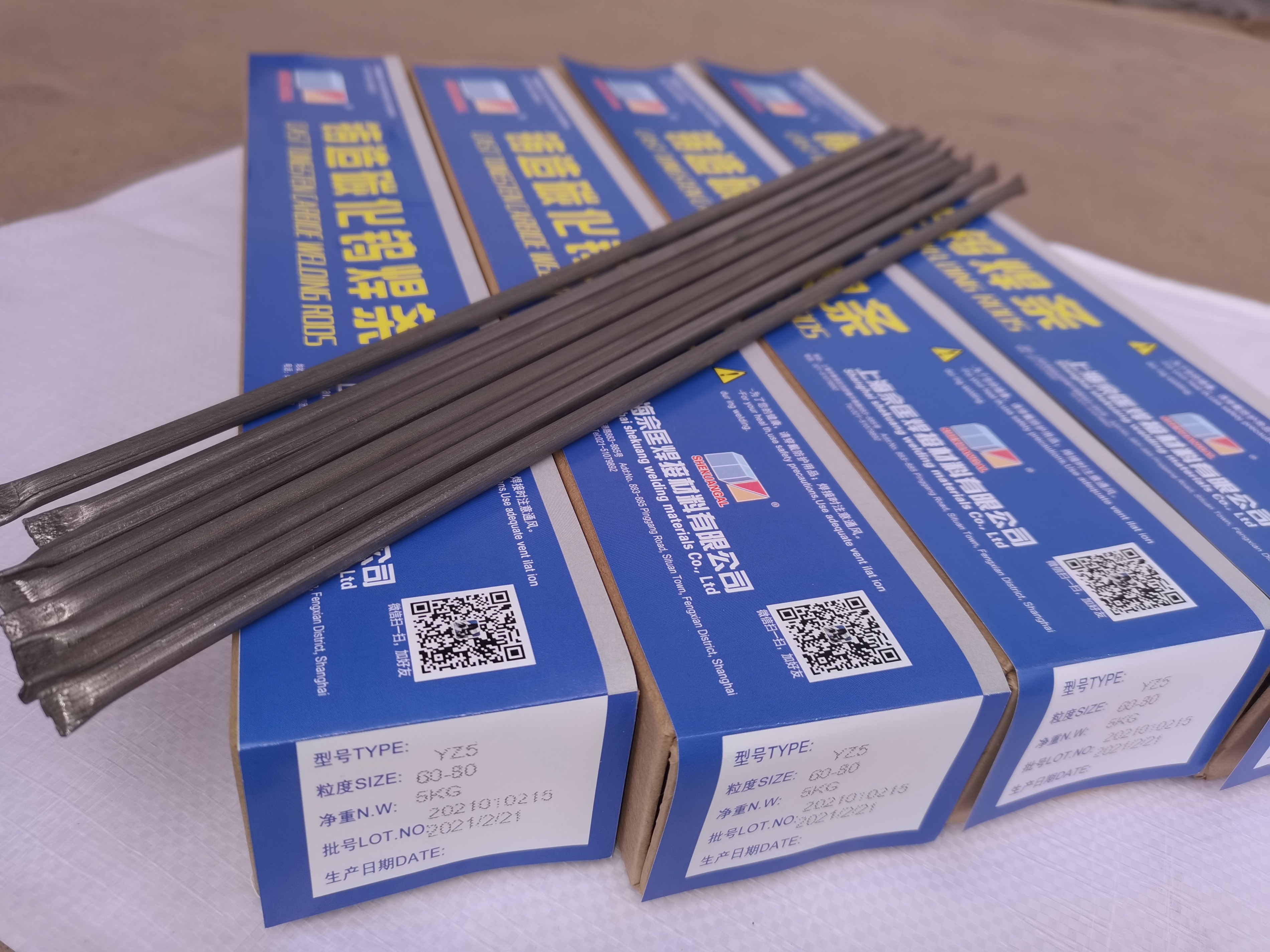

Wear resistant electrode - follow standard operating methods and precautions

BG/2005-2015- Implementation of standards

Product attributes

Impact value: Kgf/ -M/C ㎡>22%

Hardfacing hardness: HRC≧80

Operation method and precautions:

The electrode is low hydrogen coating, good welding performance, simple operation, BOTH AC and DC, dc effect is better.

(1) In the process of fusion welding, from the small current welding, the dilution rate should not exceed 35%, the electrode should not go through fast and left and right shaking, the second layer should wait for the first layer cooling slightly after the drug skin drum off again, each layer thickness of 2mm, the effect of two layers is better.

(2) The electrode should be stored in dry warehouse, if damp should be re-baked at 200℃ for 1 hour before use.

(3) If the base material has high carbon content or casting manganese and alloy parts, the base material should be preheated at about 400℃-500℃, or first use "507" low hydrogen electrode for surfacing a layer in hot surfacing, slow cooling after welding.

D708 wear resistant electrode power plant application

Power plant application scope:

1. Boiler system of power plant

Scraper slag scraper fishing machine, screw feeding type machine blade, machine blade and bellows, ball mill inlet elbow: coarse powder separator of pile body and bend: fan mill support beams and plates after hook, armor protection, short for jin, medium speed mill entrance to take over and the bellows and so on, these parts after the surfacing electrode processing multiple prolong service life.

2. Dust removal system of power plant

The blade of the induced draft fan: the baffle of the entrance regulating door, the back plate, the flue air door, the elbow of the mortar pump: the elbow of the jacket and the ash discharge pipeline, the cathode of the electric dust collector, the vibration hammer of the anode, the hammer head and the smoke plate and other equipment, after the welding electrode surfacing processing, the wear resistance effect is significantly improved.

3. Fuel system of power plant

Main equipment such as: screen screen, scraper scraper teeth, coal crusher plate and wheel hammer and coal plate, etc.

recommend products

Ranking of Similar Articles

- The silver electrode manufactu

- Wear resistant electrode selec

- Silver electrode manufacturer

- Wear resistant electrode - fol

- Wear-resistant electrode which

- Silver wire welding effect eff